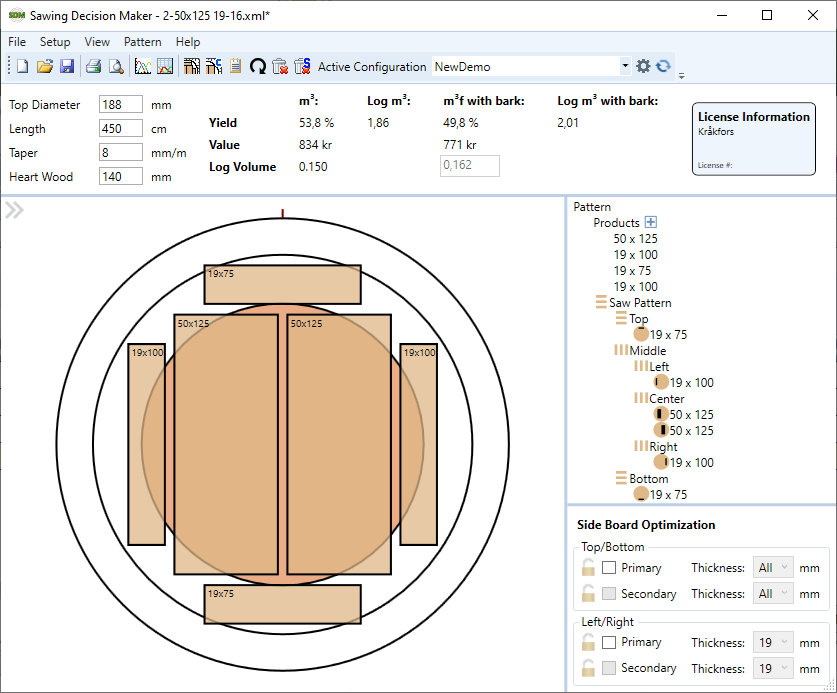

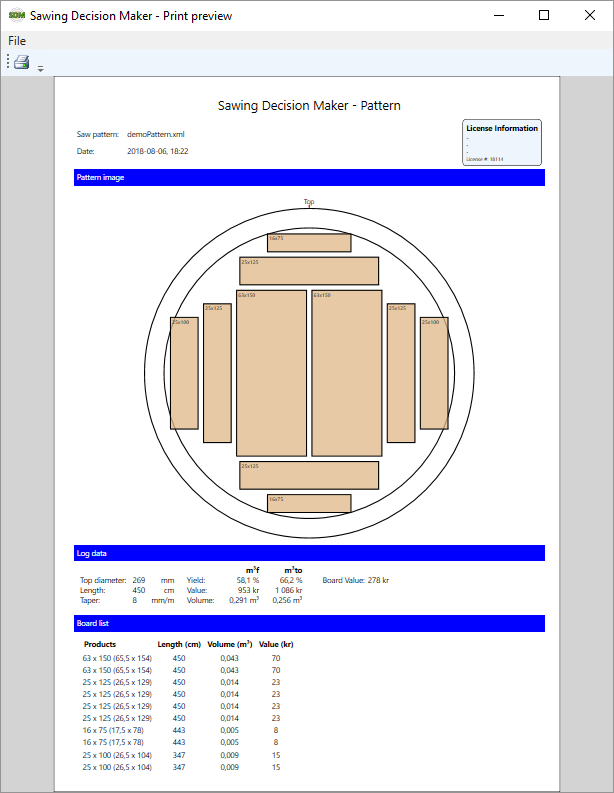

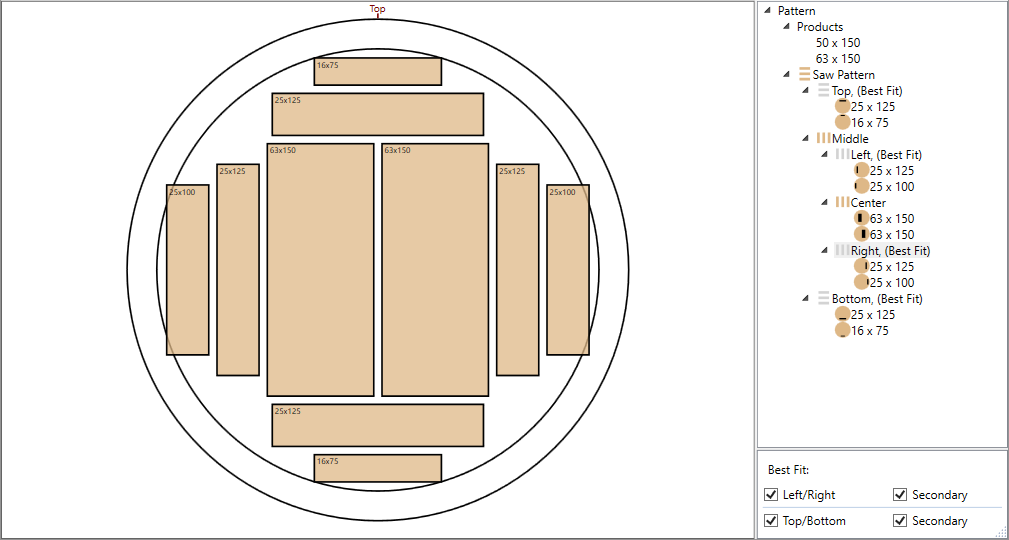

Create sawing patterns

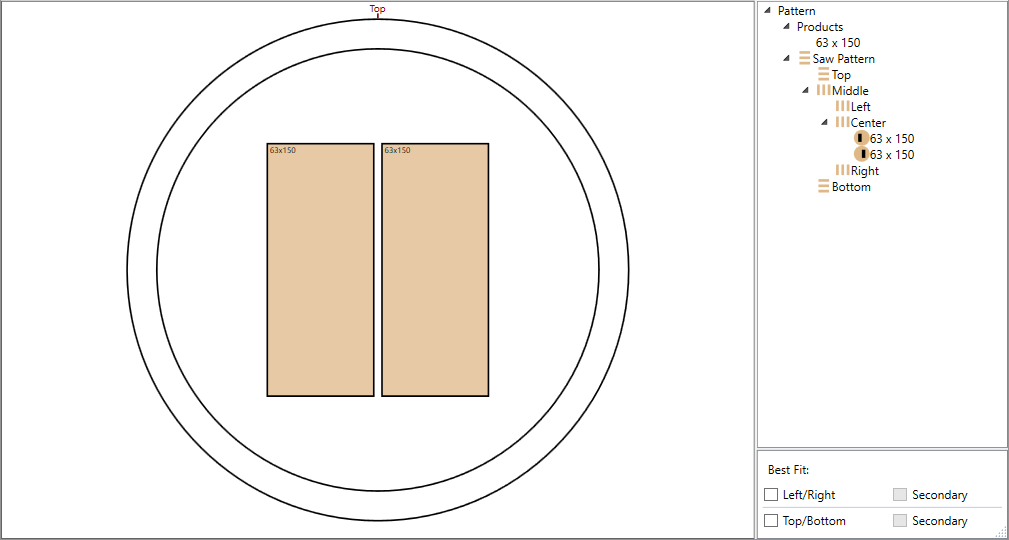

SDM provides the ability to analyze all types of sawing patterns quickly and easily.

The log dimensions, diameter, taper, length and heart wood content can easily be

varied. For a given sawing pattern the volumetric and value yield are shown along

with the contribution margin. These key figures can then be used to compare sawing

patterns to each other or to perform more sophisticated analyzes, such as variation

in log dimension. Sawing patterns can also be compared to each other with regards

to throughput in the kiln and dry sorter.

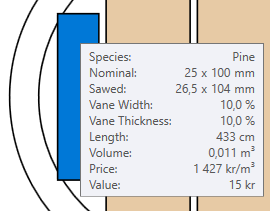

By pointing at the boards in the saw pattern the program will provide the board value, board volume, length and board data from the catalogue

Automatic sideboard optimization

After choosing center boards the program can optimize side boards with respect to maximum yield. By changing the diameter new boards will automatically be suggested in an intuitive way. Up to two boards per side can be optimized.

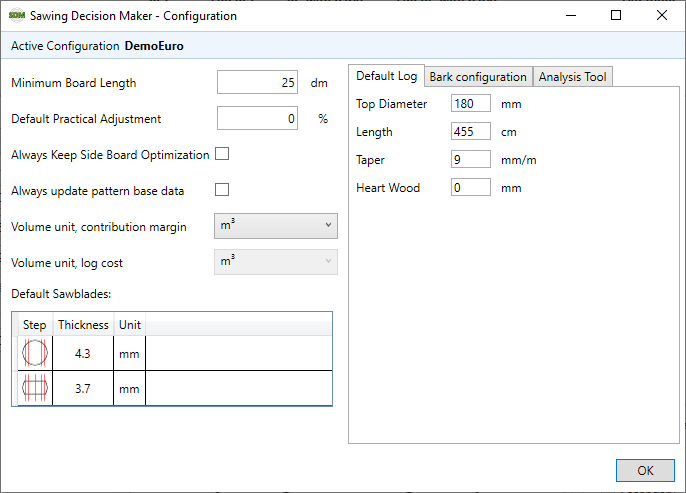

Configurations

Sawing Decision Maker let you set the minimum accepted length for boards, the saw blade thickness as well as an adjustment factor for log crookness, log ovality and sawing precision.

It is possible to have different configurations for each sawline or sawmill within a company.

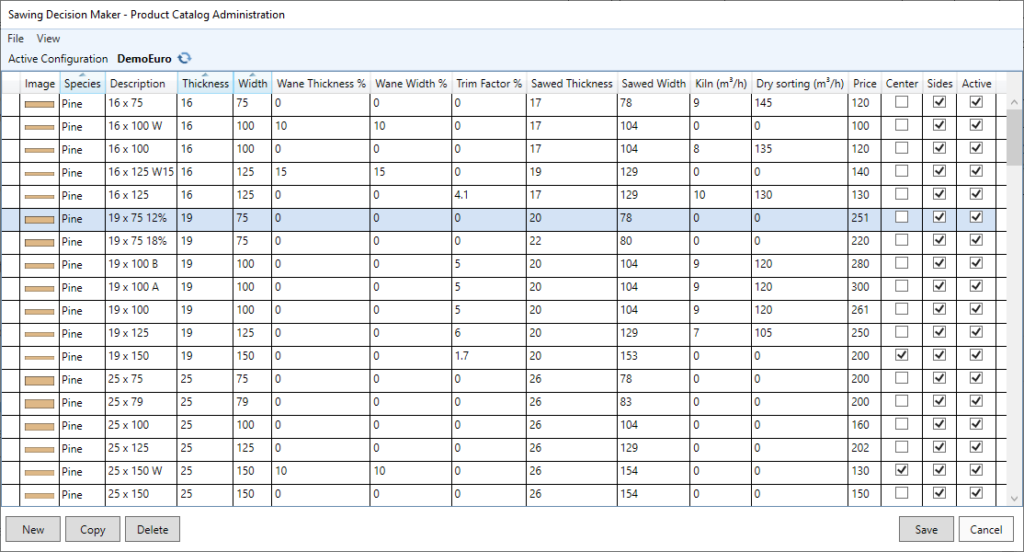

Product catalogue

A catalogue of board dimensions is built up by the user, these are some of the available parameters:

- Nominal and sawn dimensions

- Species

- Wane rules

- Price

- Center / Side board

- Length trimming factor

- Throughput in kiln/dry sorter

- Description

It is possible to have different product catalogues for each sawline or sawmill within a company.

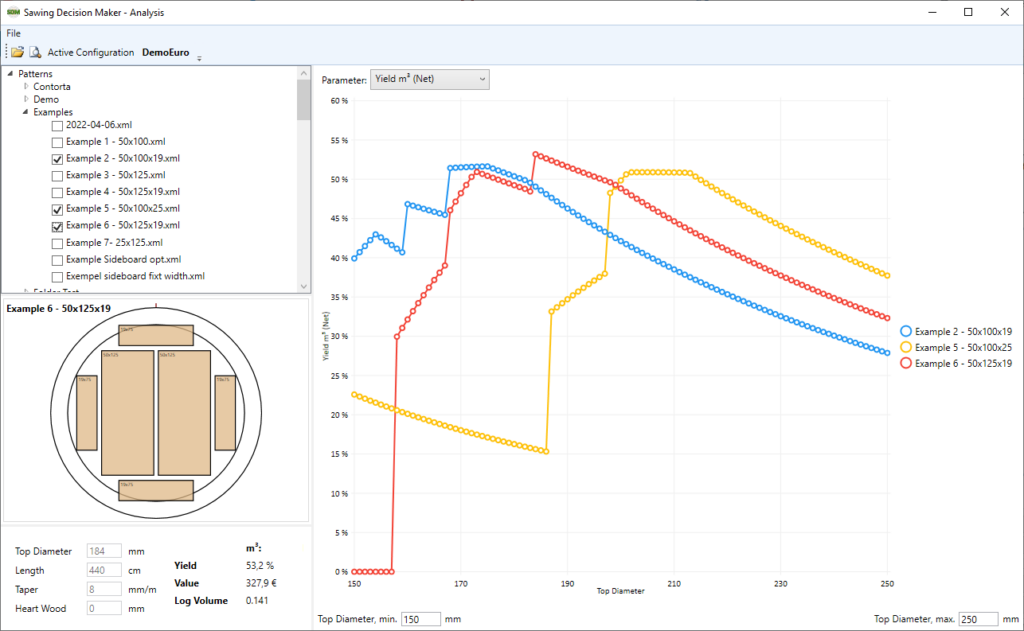

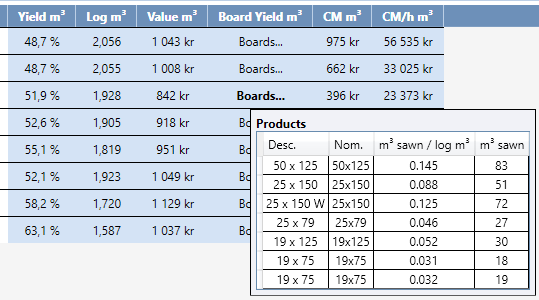

Analysis and pattern comparison

The analysis tool display a diagram with top diameter on the x-axis. On the y-axis the user can choose between volume- or value yields.

Saw patterns can be loaded into the analysis tool from previously saved saw pattern files, they can then be compared to each other. Using this tool, the user can get an indication how logs of different dimensions shall be sawn for best yield. The analysis of optimal timber utilization can be made across different markets and compared graphically.

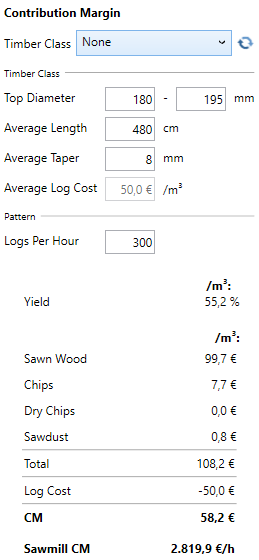

Contribution margin calculation

By using the value of sawn wood for a pattern and by entering the log cost and the value of byproducts, the contribution margin for a pattern can be calculated. The contribution margin can also be analyzed over a diameter range, which will make it an easy task to find in which diameter range a pattern should be sawn.

This can also be a helpful tool while doing an initial setup of timber classes/diameter classes.

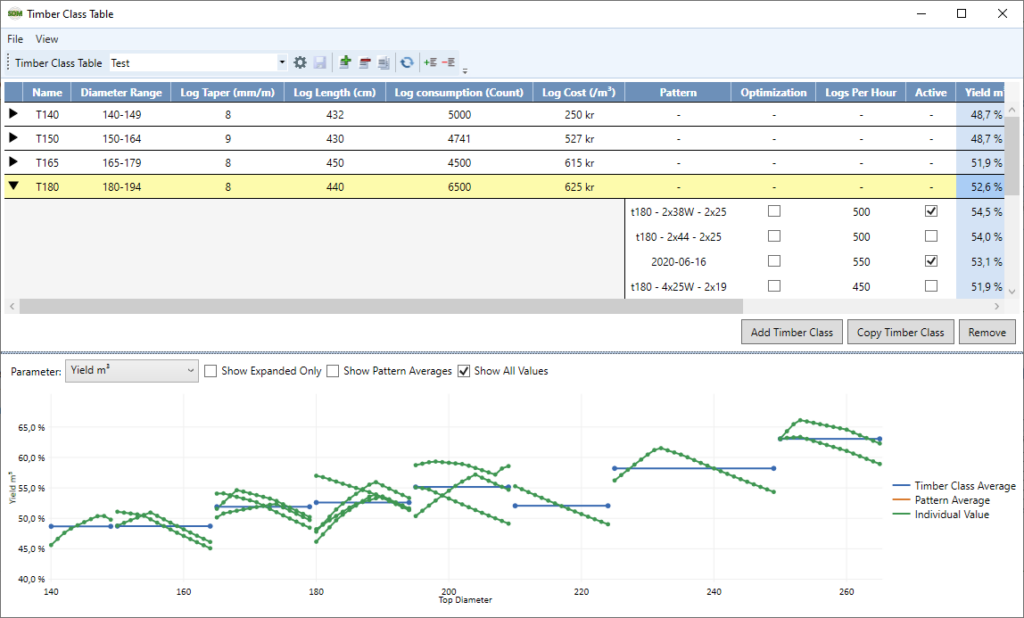

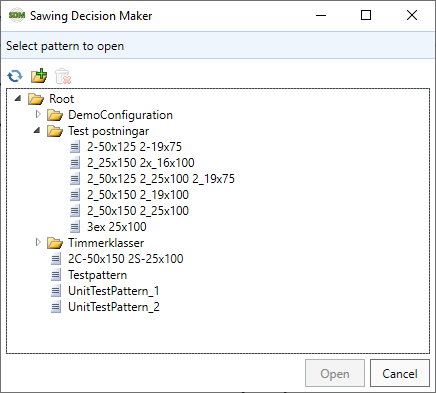

Timber class tables

A table of diameter ranges (timber classes) can be built up. Patterns can then be added to these classes. The average yield, value, contribution margin is then presented for the individual patterns along with the average for the whole timber class.

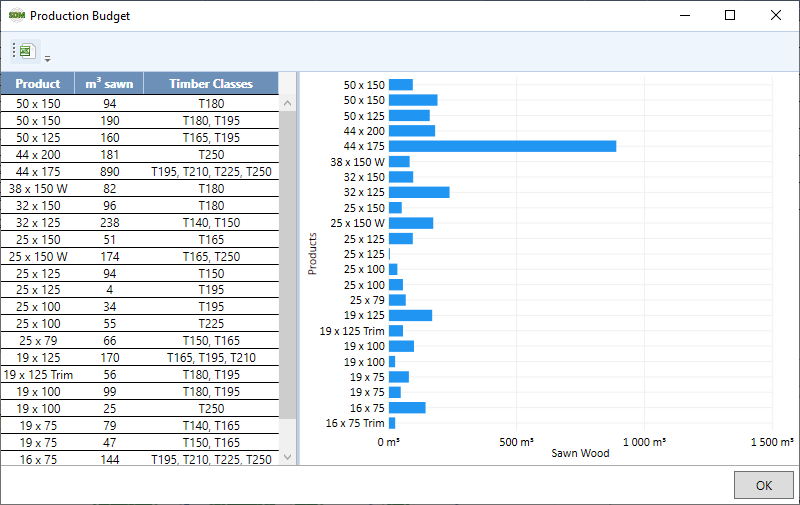

Production budget

Once a timber class table is complete with classes and patterns a production budget can be created. The user enters the amount of logs which is consumed for each timber class over a given period of time. When this is done SDM will calculate and summarize the amount of each product that will be produced and in which timber classes they are sawn. This can then be exported to Excel and used as a basis for a more detailed production budget.

File system or database storage

SDM can be used with either file system or database storage depending on user requirements.

When using our custom database solution everything from backup to maintenance is managed by Kråkfors Forest Products. The data is stored in a cloud service and can be accessed from anywhere.